Currently on the market all commercial corn oil is obtained from corn germ by either hexane extraction or a process that combines pressing/hexane extraction.

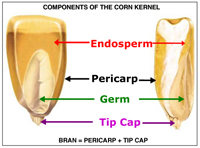

What is Corn Germ?

Corn Germ oil is estimated to contain life essential fatty acids and has a very mild taste. It is also a well known source of Vitamin E. Like all other edible oils, this oil is also used for cooking purposes especially for frying, stewing, and roasting. Apart from culinary purposes, Corn germ oil is also used as a biodiesel.

The Corn germs that are obtained through the processes of either wet degermination or dry degermination are used for the oil extraction process. The corn germs are then conditioned and flaked so that the yield of oil will be of a high quantity. After the conditioning and flaking processes, the corn germs are further fed into the oil expellers / screw presses so that the oil will be pressed in the process. The oil that is extracted through expelling is then collected and sent for filtration so that the end oil product can be used for human consumption.

Aqueous enzymatic extraction of corn germ oil was investigated. By applying hydrothermal pretreatment of corn germ, it was possible to inactivate native enzymes present in the germ and to loosen its structure. The corn was then ground and treated with enzymes. After the oil had been released by the enzyme reaction, it was separated by centrifugation. The quality of oil obtained by enzymatic extraction (Pectinex Ultra SP-L at 37°C, pH 5.2, for 6 h) was good. The oil had 1.5% free fatty acids; a total content of oxidation product value of 8.1; light yellow color (AOCS photometric color, 12.7; dominant wavelength λD=575 nm); 0.022% phosphatides; 1350 mg/kg total tocopherol; and an oxidative stability value (Rancimat test, 100°C) of 14.6 h.