palm oil process

Palm oil is an edible vegetable oil which is derived from the palm in a

palm oil processing plant. It is naturally reddish in color because of a high beta-carotene content.

The Pressing Section of Palm Oil Process

-

The palm oil process begins with the harvesting of fresh palm which are milled within 24 hours from harvesting. Palm are first transferred to the palm oil process mills for sterilisation by applying high-pressure steam, whereupon the palm fruits are enzyme deactivated and separated from the palm bunches.

-

After the pretreatment of palm oil process, the palms are crushed in a palm oil pressing machine to obtain crude palm oil. Waste and water is then cleared and separated from the CPO by means of a centrifuge. The cleared crude palm oil emerging from the centrifuge is then sent for refining while the palm kernel nut is sent for crushing. The empty fruit bunches and liquid waste arising from the process are used as fertiliser in the plantations.

-

The palm nut is fractured causing the palm kernel within the shell to contract away from the shell. The shell is separated from the kernel through a clay bath where it is used as fuel in the boiler room or co-generation plant.

-

The palm is further crushed to produce crude palm oil.

Palm Oil Pressing Plant

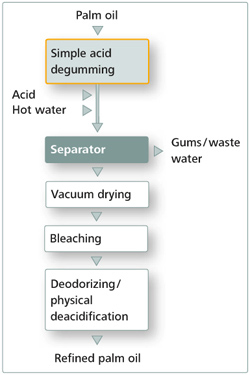

The Refining Section of Palm Oil Process

-

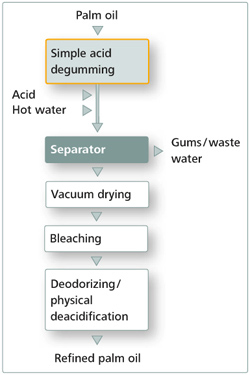

To produce refined oil, crude palm oil is processed through three refining stages, namely degumming, bleaching and deodorising. In degumming, the gum and fatty acid in crude palm oil and crude palm kernel oil are separated together with other impurities such as trace minerals, copper and iron by the application of phosphoric acid.

-

In bleaching, the oil is mixed with bleaching earth (bentonite calcium) in a vacuum room to remove impurities and colour pigments in the palm oil. In deodorising, the odour and taste of the oil is removed when the oil is steamed at high temperatures between 240°C to 260°C and then cooled to room temperature.

-

RBD palm stearin and RBD palm olein are obtained by the fractionation of RBD palm oil; whereas RBD palm kernel stearin and RBD palm kernel olein are obtained by the fractionation of RBD palm kernel oil. Through a process known as crystallisation, RBD oil is cooled until crystals are formed.

-

The crystallized oil in the crystallizer is then filtered through a membrane to separate the liquid fraction i.e. olein from the solid fraction i.e. stearin. RBD palm olein is usually sold as cooking oil and may go through further fractionation depending on the quality required.

Palm Oil Refining Plant

What Is More Can You Get from KMEC Palm Oil Process?

The palm kernel is further crushed to produce crude palm kernel oil and the remaining palm kernel meal is used as animal feed.The palm fractions can also be further processed to convert them to special value-added by-products which in various food applications ranging from healthy frying to gourmet chocolates.

Contact us to get more information on palm oil process and related machine to double your palm oil mill output. KMEC always at your service.